Let’s dive into a little bit about the handmade casting process to understand a little more about what makes Walter Bosse and Vienna Bronze items special. The casting process used is “lost wax casting” or “investment casting.” Here all the steps and love that go into the creation of a Walter Bosse model:

1. Starting with a “master”

The process begins with the artist’s “master” pattern. There are several ways to make a master: A. directly from wax to mold; B. from wax to cast metal to mold; and C. from mold to master to secondary mold.

A. If we create a master out of wax and form a mold from it directly, the wax master could be melted down or damaged in the process. With this method, the master may be lost, along with the ability to create future molds from it. But at least we have one mold for the catalog.

B. Walter Bosse’s most common method of making a master was to sculpt the wax model by hand, create a metal cast from it, refine the metal model into a finished master, and then create a new mold. This way, the metal master is saved in order to continue making future molds. This is especially useful if the original molds get damaged or need to be replaced due to use over time.

C. If the master has been lost, but the mold is still available, we can cast from the existing mold, finish the model and save it for future mold making. The only downside is that there is about 1.5–2% shrinkage. (The general shrinkage allowance of brass is 3/16″ per foot.) We would not want to keep doing this over and over again, or the model’s size will continue to shrink with each new iteration. It’s good to keep a master with each mold if possible.

2. Making a mold

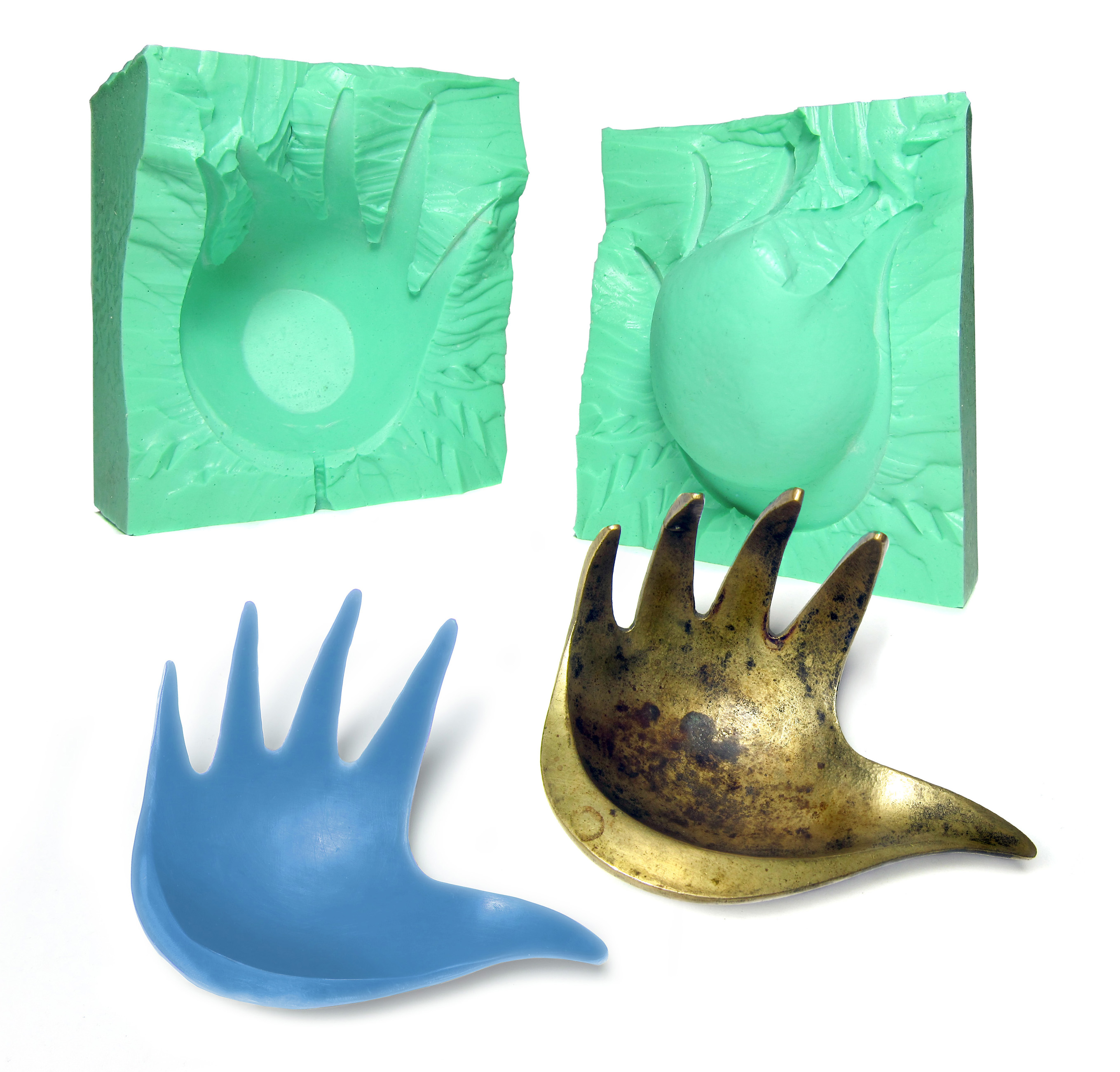

Rubber molds are preferred due to their longer shelf life. The creation of a rubber mold requires a vulcanizing press, which solidifies the shape using heat and pressure. Since quite a few of the original masters were lost, today remastering is often done with vintage Bosse pieces. In these cases, the vulcanizing process is less suitable, as the heat and pressure can be rough on vintage originals. Silicone molds are therefore used to preserve the quality of the vintage original (though the silicone molds do not tend to last as long). The vulcanized rubber molds end up lasting 10–20 years with regular use, while silicone can last only 2–5 years.

It is necessary to cut a sprue hole in the mold, preferably somewhere inconspicuous on the model, running from the widest or thickest part to the thinnest part. This will be the path the wax/metal flows most easily into the mold. The master must then be cut from the mold, either by prying the mold open enough to remove the master, or cutting it in half entirely to make a two-part mold. It is best to cut the mold with a very sharp blade, such as a scalpel.

Please Note: It takes a great deal of time, effort, and money to maintain the museum collection, host this website, create informative posts, and respond to authentication and identification requests. Thank Alyssa for her expertise and authentication assistance here—tips are greatly appreciated!

Buy a Coffee for Alyssa!3. Wax

Molten wax is injected into the mold through the sprue hole. The wax model is then removed from the mold. An extended sprue is attached, which is then connected to a sprue base/post which makes up the center of the wax tree. We add as many wax models to the tree as possible to fill up all the available casting space.

4. Adding investment

Once the wax tree is full of models and ready to cast, it’s time to add the investment. The investment is what’s left when all the wax is burned out, leaving space for molten brass to be poured in. The flask/cuvette is placed around the tree. The investment medium, usually a type of plaster material, is mixed and added around the wax tree inside the flask. All of the bubbles must be sucked out, best performed with a vacuum or vibration method. Once the investment is cured, we are ready to burn out the wax.

5. Casting

The molten brass is poured, and begins to cure. Once the metal has cooled, the tree and investment material are removed from the flask. The investment is slowly and carefully broken away from the brass models. Once the models are fully cleaned of investment, they can now be snipped off the tree, ready for finishing.

6. Finishing

The models get a thorough grinding and polishing to ensure there are no flaws. They are then stamped on the bottom with “Bosse Austria,” and undergo the patented patina process. The model then goes through a second polishing in selected areas to highlight the gleaming beauty of the natural brass.

With finishing complete, a beautiful new Walter Bosse work of art emerges, ready to find a home!